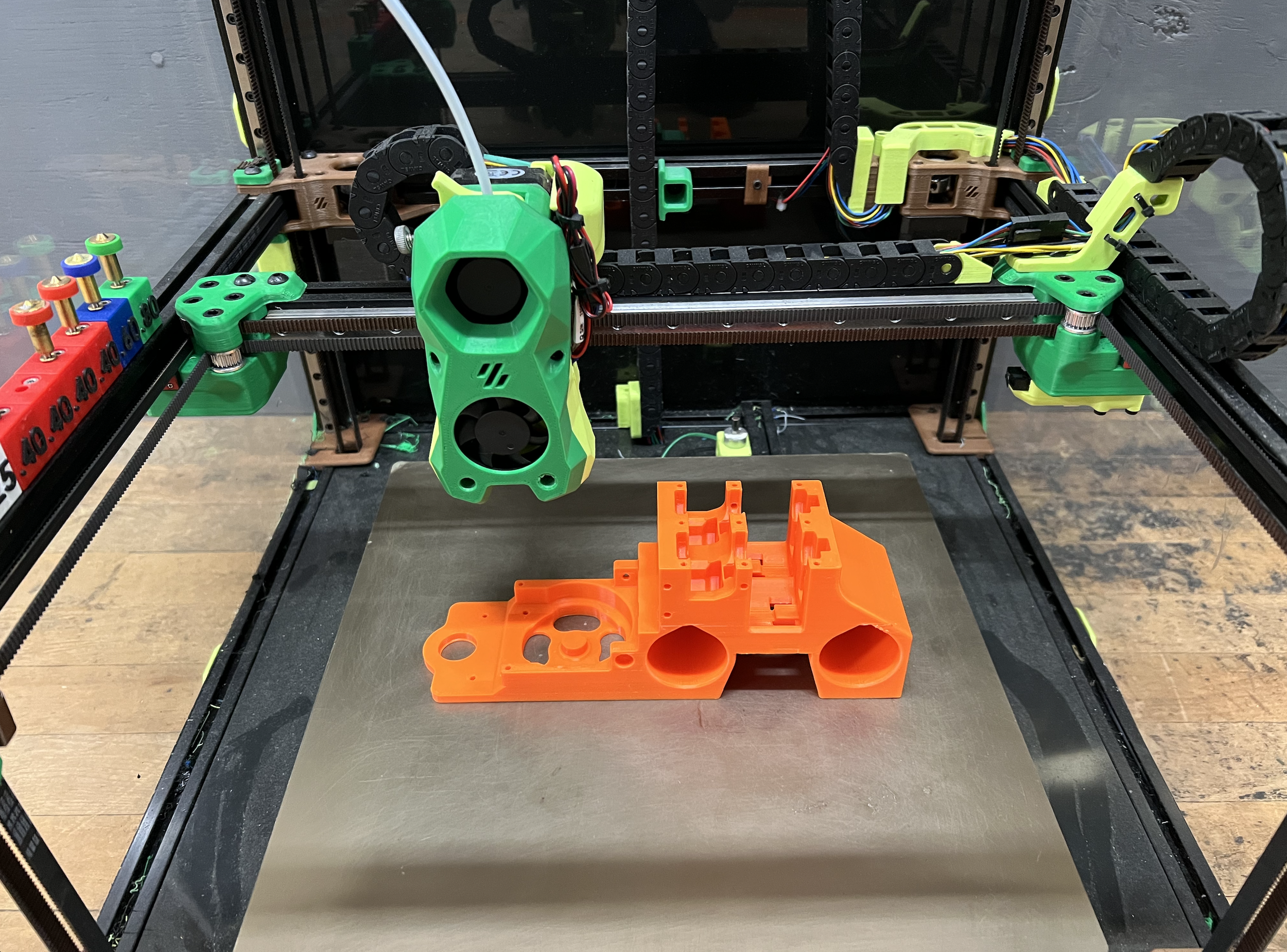

Voron 2.4 - FDM 3D Printer

This is my Voron 2.4, an open source 3D printer. I built this printer to solve some shortcomings of my previous printer, my Prusa Mk3. My Prusa made excellent PLA & PETG parts, but it did it slowly and did not do well with other materials. The Voron matched the part quality of the Prusa, but could printer larger parts and with more materials. Particularly the printer could print compliant materials and thermally sensitive materials reliably. I also implemented resonance compensation on the printer, which allowed it to print more than double the speed of my Prusa, at the same quality.

Playing with Carbon Fiber Composites

I’ve always enjoyed riding pennyboards and electric skateboards, but I noticed that, at higher speeds, the vibrations made the ride feel rougher than I’d like. When a friend got an electric skateboard with a composite deck that worked like a leaf spring, smoothing out the vibrations, I was inspired to try designing a shortboard with similar technology. I wanted to explore how to integrate a form of suspension directly into the deck itself.

To build familiarity with composites, I started by experimenting with a standard composite deck. My goal was to understand the fundamentals and learn what it takes to design a board with the ideal balance of flexibility and strength. Through research and early tests, I gained insights into material behavior and design considerations for high-speed applications.

After some initial testing, I learned that the original skateboard used a woven basalt layer in its design—a material I couldn’t source for my own build. While this meant pausing the project, it opened my eyes to the complexity and specificity of composite design. I now have a deeper appreciation for material selection in performance engineering.